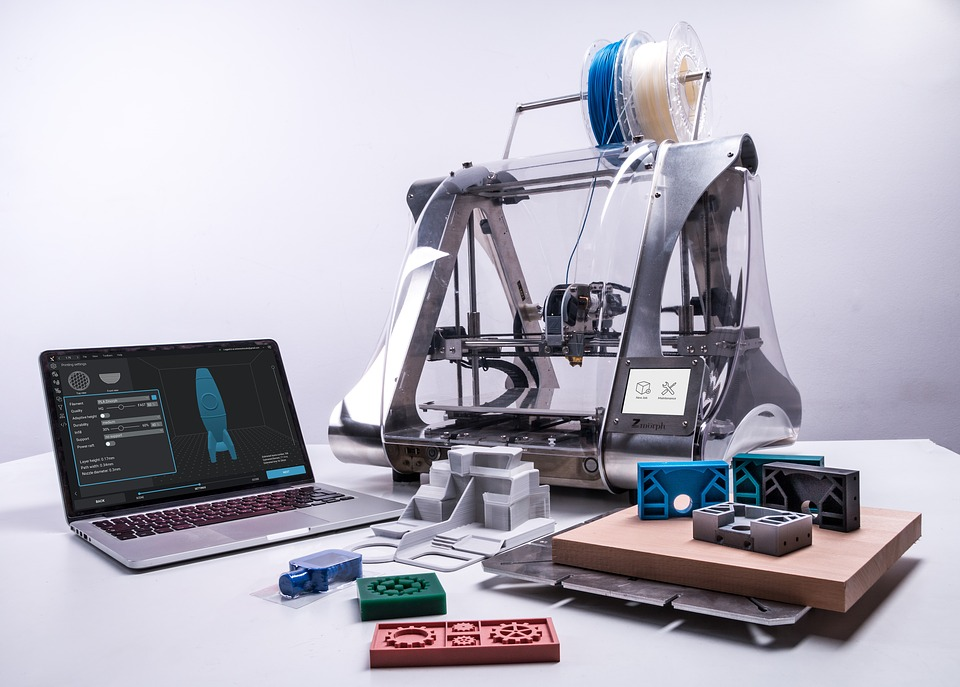

3D printing and prototyping technology have revolutionized the manufacturing world, allowing individuals and companies to create customized products with ease. As technology and gadgets continue to shape our everyday lives, the potential of 3D printing becomes increasingly valuable. In this blog post, we will explore how 3D printing and prototyping unlock their potential in technology and gadgets.

1. Faster Time to Market

3D printing enables a faster time to market by reducing the time needed for the product design and development cycle. Instead of waiting for traditional manufacturing, 3D printing allows prototypes to be created quickly, reducing the time needed for creating a product from months to weeks or even days. This accelerated timeline makes it easier for businesses to launch new products that cater to the ever-changing needs of their customers.

2. Simplified Design Iterations

The technology used in 3D printing enables designers to create intricate models with ease. This allows designers to iterate and refine their designs until they are perfect, without the need for costly and time-consuming manual manufacturing processes. With 3D printing, the product development process can speed up substantially, meaning an individual or business can produce, test and make design changes quicker than ever before.

3. Customization

The ability to create customized products is one of the most significant benefits of 3D printing. The ability to create prototypes at a low cost means that businesses can offer customizations to their customers. Using 3D printing and prototyping, consumers can have personalized tech and gadgets that fit their individual needs and preferences. This customization can help businesses stand out in competitive markets, build brand recognition and increase customer loyalty.

4. Reduced Costs

3D printing reduces the cost of the product design and development process by eliminating the need for complex and expensive manufacturing equipment. This technology does not require expensive materials or labour intensive manufacturing processes, so it allows businesses of all sizes to create prototypes and products at a lower cost than traditional methods. This cost-effectiveness per prototype is beneficial, especially, in the early stages of product development.

5. Enhanced Functionality

Using 3D printing and prototyping, manufacturers can create gadgets that are more durable, functional, and efficient than traditional manufacturing methods allow. The design freedom provided by 3D printing enables features to be added easily, such as hinges, parts that move or even mixing materials, which may not be possible using traditional manufacturing techniques. This ability to create intricate parts that are functional and robust expands the possibilities of what new technology and gadgets can achieve.

In conclusion, 3D printing and prototyping are technologies that are transforming the business manufacturing landscape by providing an opportunity to create customized products cost-effectively and at an accelerated timeline. These technologies have tremendous potential for the design and development of technology and gadgets by reducing time to market, simplifying design iterations, enabling customization, reducing costs and producing products with enhanced functionality. By incorporating 3D printing and prototyping into their product development cycle, businesses can unlock their potential for innovative approaches to product design and development.