Unlocking the Potential of 3D Printing and Prototyping

Are you ready to dive into the world of 3D printing and prototyping? In recent years, this groundbreaking technology has transformed various industries, enabling faster and more cost-effective product development. From manufacturing and healthcare to architecture and fashion, 3D printing has unlocked unprecedented possibilities. In this blog post, we’ll explore the potential of 3D printing and prototyping and how it can revolutionize your business.

1. Rapid Prototyping: Saving Time and Money

One of the most significant advantages of 3D printing is its ability to accelerate the prototyping process. Traditionally, developing a physical prototype would require extensive time, resources, and multiple iterations. With 3D printing, you can turn your digital design into a tangible model within hours or even minutes. This rapid prototyping eliminates the need for costly tooling and rework, saving both time and money in the product development stage.

2. Customization and Personalization

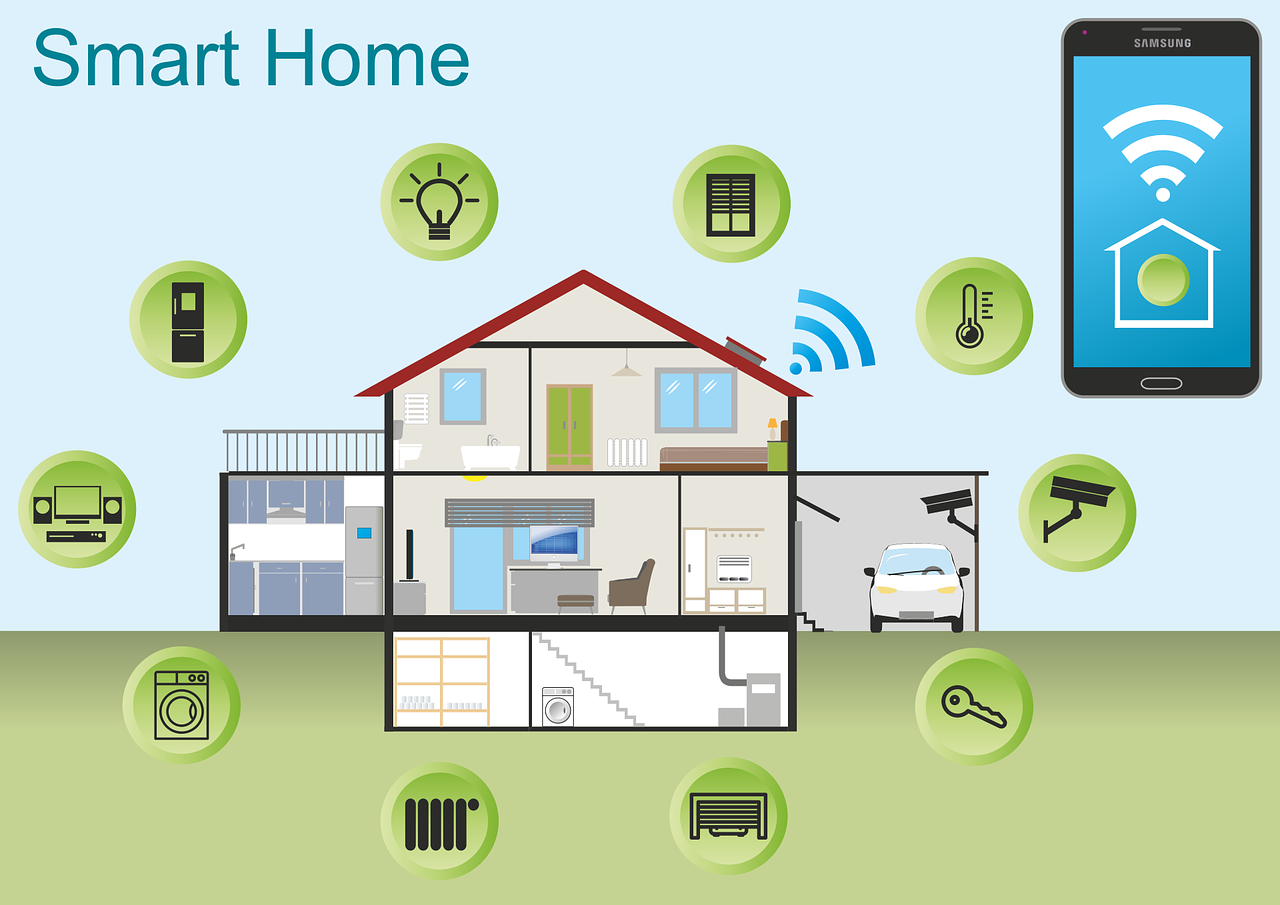

Gone are the days of one-size-fits-all manufacturing. 3D printing allows for unparalleled customization and personalization. Whether you’re designing consumer products, healthcare devices, or even architectural models, 3D printing enables you to create unique and tailored solutions. Companies can meet individual customer needs and preferences without sacrificing efficiency or cost-effectiveness.

3. Complex Geometries and Intricate Designs

The freedom of design provided by 3D printing is unparalleled. Unlike traditional manufacturing methods, 3D printing allows for the production of complex geometries and intricate designs that were previously impossible or challenging to recreate. With this technology, you can unleash your creativity and design products with intricate details, organic shapes, and exotic structures.

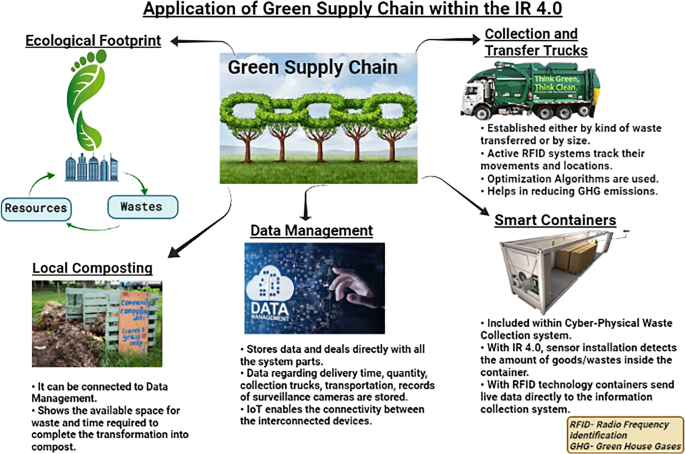

4. Reduced Material Waste and Sustainability

3D printing is a more sustainable alternative to conventional manufacturing processes. Traditional subtractive manufacturing methods often involve excessive material waste. In contrast, 3D printing is an additive process, where materials are added layer by layer, reducing waste significantly. This technology also enables the use of recyclable and biodegradable materials, promoting a greener and more sustainable approach to production.

5. Accelerated Time-to-Market

The rapid prototyping capabilities of 3D printing contribute to faster time-to-market for new products. By reducing development cycles, businesses can iterate swiftly, test multiple design variations, and gather user feedback before finalizing their products. This agility allows companies to respond to market demands promptly and gain a competitive edge.

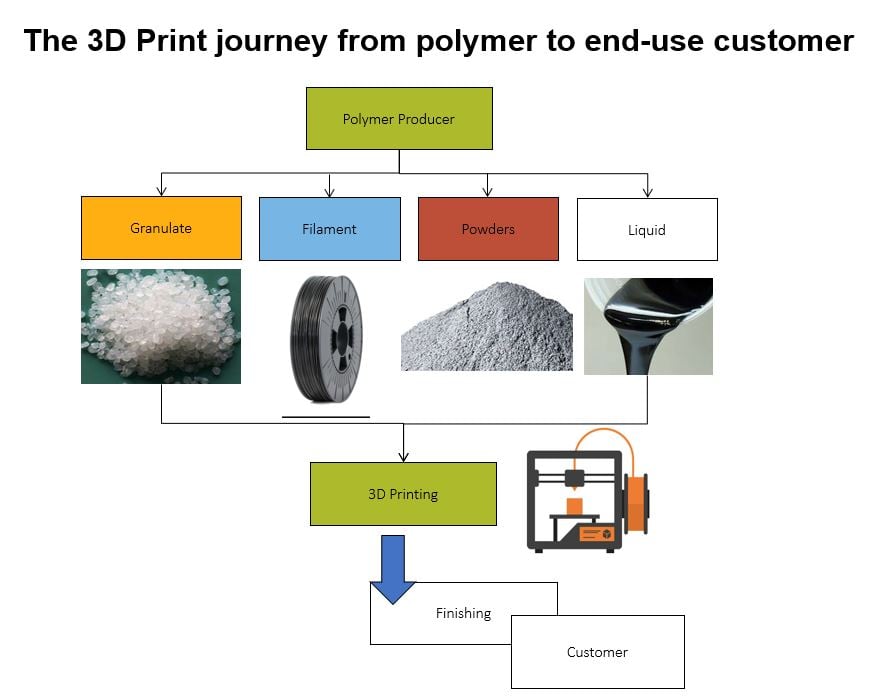

6. Supply Chain Optimization and On-Demand Manufacturing

Another game-changing aspect of 3D printing is on-demand manufacturing. Instead of maintaining large inventories, businesses can print products as they are needed, minimizing storage costs and the risk of overstocking. This approach enables businesses to optimize their supply chain, reduce lead times, and respond efficiently to fluctuating market demands.

7. Enhanced Collaboration and Communication

3D printing technology has revolutionized collaboration and communication between designers, engineers, and stakeholders. Digital files can be shared easily and printed remotely, allowing for seamless collaboration across different locations. This convenience streamlines the decision-making process, reduces misunderstandings, and ensures all parties are on the same page during product development.

In Conclusion

The potential of 3D printing and prototyping is boundless. By harnessing this technology, businesses can realize faster product development, customization, complex designs, sustainability, and improved supply chain management. Embracing 3D printing unlocks a new world of possibilities, propelling your business towards innovation and success. Stay ahead of the curve and start utilizing the power of 3D printing today.